Boler Axle

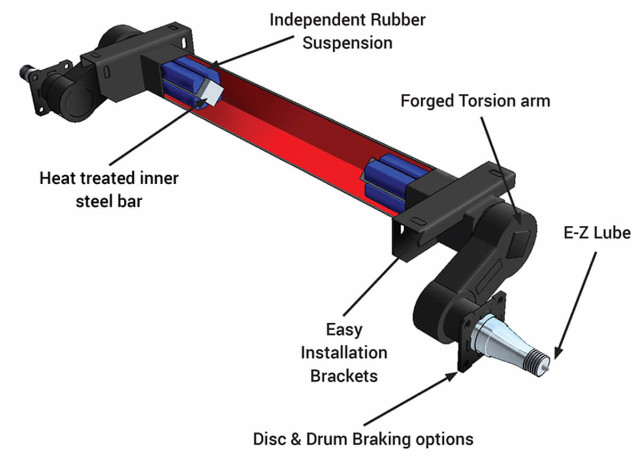

The original Boler came equipped with an Ingersoll Rub-R-Ride rubber torsion axle and later was replaced with the Dexter Torflex. Rubber torsion axles are a good system that requires little servicing other than the usual bearing repacking and maintenance. One very unusual aspect is that the axle in the Boler is actually installed backwards. These axles are designed to be installed so that the suspension arm trail behind the axle tube, the wheels are pulled behind the axle, but the Boler designers saw the opportunity to install the axle tube behind the step in the kitchen leading up to the dinette area, but to locate the wheels in the correct location for proper trailer balance the suspension arms need to point forward (called a leading axle), the wheels are essentially being pushed down the road ahead of the axle.

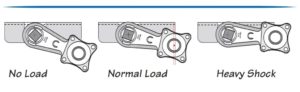

There does not appear to be agreement on what the original Boler used as the start angle, I believe the angle they used was a 0° or 10° up angle but this I cannot confirm. An initial setting of zero degrees or a slight up angle will maximize the suspension geometry and provide the smoothest ride. The reason for this is that when the arm is positioning upward and being pushed down the road the impact or compression of the suspension arms arcs toward the rear of the trailer following the direction of travel, if the suspension arms are is positioned at a down angle any compression actually forces the wheel forward against the direction of travel which results in a harsher ride.

NOTE: NEVER jack up or lift your trailer by the axle!!!

Place the jack on the frame behind the axle as close to the mounting bracket as you can. Lifting the trailer by any part of the axle will bend the axle and replacement of the axle will be needed.

Replacing your Axle

Over time the axle will wear out, the rubber elastomer will deteriorate with use and age. As the elastomer deteriorates the axle will start to sag, causing the trailer to sit lower, there can also be movement laterally in the torsion tube which will cause the wheels to toe out, this can cause slight swaying and tire wear. The most noticeable result will be a harsh ride, often noticed by seat cushions flying everywhere, cupboard doors open and even bouncing of the trailer even when the road appears smooth. As a general rule of thumb an axle that is 15-20 years old probably needs replacing.

How do I check my axle for wear?

According to the Dexter engineers “Dexter would consider any Torflex arm that has moved more than ten degrees from the original build angle as weak or losing suspension”. But how would you know if your axle has sagged 10° or more when you don’t know what the start angle was?

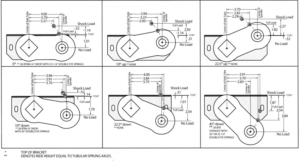

The first test is to jack up each side of the trailer and watch to see if the wheel moves down as weight is removed from that side, if on either side the wheel does not drop at least 1½” the axle needs replacing. Second, measure the diameter of your tire (as an example ST175/80D13 trailer tires have a diameter of 24″) and divide this number by 2 (in this case 12″). Now with the trailer sitting on level ground measure the distance from the ground to the top of the axle tube, either just ahead or behind the axle mounting brackets. Take the tire radius and subtract the frame to ground measurement, if the result is greater than 2½” your axle needs replacing (the above calculations are based on a fully loaded axle with an initial start angle of 0° to 10° up angle).

In the above example R=12″; Frame to ground = 11″ (12″-11″=1″ axle is good)

As an example: your trailer has ST175/80D13 tires which have a diameter of 24″, dividing the diameter by 2 gives you the radius of 12″.

The distance measured from the ground to the top of the axle measures 7″

12″-7″=5″ The axle arm has dropped more than 2″ and should be replaced

How do I order an Axle?

When replacing your axle there are a number of items to consider, these include:

- Axle weight capacity

- Axle arm start angle

- Axle bracket spacing

- Hub face to face measurement

- Brakes

- Axle type or manufacturer

- Axle orientation (leading arm vs trailing arm)

NOTE: Axle weight capacity

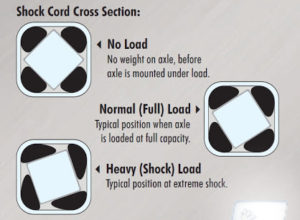

Bigger is NOT better. The axle capacity is determined by the weight of the trailer, you want the suspension to work within the range it was designed to carry, if you put an axle on that is rated too low then the suspension will be at or near the maximum compressed range, when you hit a bump the axle will not absorb the bump and send the shock through the trailer and frame (bottom out the suspension). If you put on an axle that has too high a capacity, like a 3500 lb axle, the suspension will resist moving and again any bump will be sent through the trailer and frame. Ideally you want the capacity so that the suspension is slightly compressed when the trailer is just sitting, when a bump is hit the suspension compresses and absorbs the impact rather that transferring it to the trailer and frame.

Reviewing real world trailer weights the originally advertised dry weight for a Boler of 900-1000 lbs is not realistic. The average weight identified by owners is in the 1400-2000 lb range, therefore a 2000 – 2200 lb axle is the ideal range for the 13′ Boler

Axle Arm Start Angle

The axle arm start angle is one of the primary factors that determines the ground clearance or ride height of your Boler. In most instances you are replacing your axle because it is worn out, as the elastomer deteriorates the ride height goes down and ground clearance becomes less, so don’t just guess at the start angle, read on.

Some things to consider when deciding on the final ride height and ground clearance of your Boler.

- The original axle used on the Boler was 10° up which makes sense considering the axle orientation with the frame, so use those measurements in the table as a starting reference, NOT the measurements from your Boler with its worn out and sagging axle

- The roads or terrain you will be traveling on, rougher or rutted roads need more ground clearance than paved highways. As a reference the average pick-up truck has 8”-10” of ground clearance.

- The height of the step-up, the average step riser is about 7”-8”, more can be awkward, again the original 0° or 10° up results in the ideal set-up height

- Since the standard Boler axle is installed as a leading arm, a 0° or 10° up is beneficial because suspension movement arches in the direction of travel which provides a smoother ride, a down angle will result in a rougher ride because the arm arches against the direction of travel.

- Axle Start Angle: the angle of the torsion arm relative to the horizontal plane, stated in the unloaded condition. This angle is a factor in determining the frame height. (quote from Dexter definitions)

- Mounting Bracket Height: two bracket heights are available, the Low Profile Bracket which is the standard mounting bracket, and the High Profile Bracket which will add 0.88” additional ground clearance

The measurements in the following table indicate the average ride height for a Dexter #9 axle, the ± provide the range from no load to full load.

Axle 22.5° down 10° down 0° 10° up 22.5° up Ground clearance 10.57” ±1.15” 9.29” ±1.17” 8.27” ±1.15” 7.29” ±1.09” 6.15” ±0.97” Ground clearance 11.45” ±1.15” 10.17” ±1.17” 9.15” ±1.15” 8.17” ±1.09” 7.03” ±0.97”

Start Angle

Low Profile Bracket

High Profile Bracket

Replacement Axle Specifications

Dexter #9: 2000 lb – 2200 lb with brakes

Bolt circle: 5×4.5″

Start angle: 10 deg up

Bracket type: Low Profile (if extra ground clearance needed use high profile brackets)

Bracket spacing (outside to outside frame): 48″

Hub face to Hub Face: 63″

NOTE: Double check all measurements on your axle

A final comment: I highly recommend when you order your new axle always have brake installed. You may not think it is needed but trust me, that one time when you least expect it those brakes will be worth every penny. Please see the section on trailer brakes, Boler brakes need to be installed on the opposite side in relation to the standard axle installation.

barbe s

Ian, This site is so helpful – I’ve printed off the info about the axle & installation to take to the RV shop in Princetons & you indicate on the axle site to see the section on trailer brakes, however I cannot locate the section on Trailer brakes for the Boler… am I overlooking it?

Ian

Thank you Barbe, many of the article are being written so some content is missing at this time.

Clayton

Hi, I’m curious as to whether or not the old axles are hub centric or lug centric. I would like to install regular car rims, not trailer wheels and everything I read talks about wheels for trailers need to be hub centric. My trailer is a 1974 and the typical trailer wheels weren’t around back then so it lends me to believe the original wheels were lug centric, so the axle should be also. Thank you in advance for your help.

Ian

The axles and wheels are lug centric. Trailer rims usually have zero offset so if considering using automotive rims make sure the offset is compatible with work on your Boler

Albert

Ian,

This was a great article to read up on. I did replace the axle on mine with one of 2500LBs. This seems to work very well. I was curious to know what your findings and recommendations would be on tire replacement. I’m currently on 13″ wheels, but I’m finding them to be somewhat unstable. I would like to maybe explore some wider tires. any suggestions?

Ian

The tire I recommend and it is the old tire I will run on my own Boler is the Maxxis M8008ST in 175/80R13 size

Harold Coish

I have 1977 Boler 13 ft. trailer. The Dexter #9 axle doesn’t fit . the bracket is off by 1 inch. Why would say it’s fits?

Ian

Harold, the Dexter axle can be built to any width and using a selection of different brackets. The one you were probably looking it was a pre-built unit that one “buys off the shelf”, it also was probably supplied with zero angle on the arms. You need to custom order the axle to specification you provide to the axle supplier, if you axle supplier says they cannot do that then find a new supplier, reference the Dexter website for authorized dealers

Joe

Hey Ian

Your thoughts on replacing the axle with a leaf sprung?

Thanks

Joe

Ian

Hi Joe, The torsion axle is a far superior suspension system, it provides independent wheel movement on each side, gives a smoother ride and is maintenance free. Leaf springs are an archaic although common system because they are very cheap to produce. But ultimately it is your choice if you want to change to a leaf spring axle.

Bob McD

Hi Ian. My guess is the axle measurement doesn’t work with a 17 foot Boler. There is a leaf spring present and 14 inch tires, neither of which are in your example and photos above. My radius is 12+3/4 inches and the ground to frame is 16+1/2 inches. Each wheel drop when lifted is about one inch which is way under your “at least 1+1/2 inch” statement. Perhaps none of this applies to the 17 foot?

Ian

Your right Bob, the information in this article is for torsion axles and do not apply to leaf spring suspension. On leaf springs inspect the springs for broken leaves, word bushings, or tire wear caused by a bent axle.

Geoff Squires

Hi Bob. I have been running 14” mags with light truck tires (load Spec 96S) from a Ford Ranger truck on my boler 17’ and they worked very well as lug centric rims. I had to ream out the centre hole with a dremmel tool so the rims would fit over the hub ( I removed the excess alloy with a hand tool so it was not possible to make a perfctly symmetrical hole.) This year i have upgraded to 17” alloy wheels from a 2003/04 G53 Infiniti. The hub size is perfct for my axel hubs. I am running 265/70R17s radial Bridgestone Dueller H/T truck tires with road rating 110S so they will easily handle the trailer wieght and should tow smoothly. Lots of clearance to the wheel well but i think iam going to add 1.5” wheel spacers to make up for a slightly different offset.

Tim MacDonald

Great info. I printed it off and took my old axle into city spring in Edmonton. 1 day later and $450 I had a new axle

Thank you

Maxime

Hi, i’m a new owner of a Boler 1973. As i was changing my tires for new ones… one side of the trailer suspension was to realy hight in the boler wheelwell and i was not able to remove or install the wheel. In order to put back the wheel … i had to forced down the suspension arm to be able to put the wheel in !

Any idea of the problem ? Do i need new torsion axle ?

Thanks,

Maxime

Ian

What you describe is normal and the way the boler was originally constructed. The boler body is offset on the frame by 1″ towards the kitchen size, this makes the kitchen a bit bigger but also results in the tire clearance to the body being different side to side. If you axle is bolted to the frame you can sometime loosen the bolts and move the axle sideways slightly to even it out some. To determine if your axle needs replacing refer to Torsion Axle – everything you want to know

Maxime

Ok great ! Realy appreciate your help.

Thanks,

Maxime

Dominique Davidson Befus

Hi. I just bought a Boler in May and I’m worried because the wheel is about 1 cm from the seal/rubber of the body on the door side. I’m stressing that it may rub when hitting bumps…

I noticed my door doesn’t perfectly line up with the frame so the frame may be a bit warped although I don’t see any big cracks or damage. I’ve just checked the axle and it looks horizontal (loaded with my stuff…) 0*. Also, my clearance is good (at 10 inches/ 12-10=2.).

Should I bring it somewhere to get it checked? Any guidance would be great.

Dominique

Ian

As an FYI the boler body is offset on the frame 1″ towards the kitchen side, this makes the kitchen 1″ larger but also means the tire clearance is different side to side. One tire will be much closer to the body than the other side. Although the tires are close in most cases they will not rub. If your axle is bolted to the frame you may be able to loosen the bolts and shift the axle slightly sideways to better center it under the body rather than having it centered under the frame.

Reggie

I’m building a utility trailer using a torsion axle. Can I weld the axle to the frame as opposed to bolting it to the frame? Which way is recommended, welded or bolted?

Ian

You can weld or bolt the axle, just remember you can only weld on the axle brackets, NOT the axle tube. The heat from welding on the axle tube will destroy the elastomer and ruin the axle. With bolting you can easily change or adjust the axle if needed.

Mark E Naber

I have an opportunity to purchase a torsion axle that is what I need except for the mounting bracket spacing. Is it a hard rule that the mounting brackets are located on the outer frame. If the are in 6 inches on each side does that affect the performance of the axle? We are rebuilding the frame so we can easily accommodate extra support for this mounting location.

Ian

I’m not sure if it would work. The most important measurement is the hub faces where the wheels mount, these have to be correct so the wheels are located correctly. The axle is designed to mount on the side frame rails, to mount the axle inside those rails poses lots of problems, because of the dropped floor in the kitchen area. You cannot modify the frame with cross braces through where the axle mounts without installing structural cross beams below the floor section (where the axle usually sits) which would raise the ride height considerably

James Love III

I am in desperate need of a torsion axle for my 1991 coachman Clarion. I can’t seem to find anyone who knows anything about these or where I can order one. Need help.

Ian

There are two manufactures of torsion axles and they have distributors across North America. Check on these pages to find the axle and location. Torsion axles are custom made and these local distributors can make the axle to your specifications.

Dexter Axles and Flexi-Ride

Reggie

I have four Rigid Hitch torsion axles rated 3,500lbs. They look the same as what you’re looking for. They are 8’ long outside to outside. The mounting points to the frame of your trailer are 74” outside and 69 and 1/2” inside. Part no. TA-374-30. Bracket 30 degree below starting angle. They are complete with hubs and bearings. Let me know if you have any questions.

Paul Peca

I also ran into all sorts of unknowlegeable people while trying to replace my 1983 Boler Rub R Ride axle.I finally found an exact replacement off the shelf at the Standard Axle Co.Ltd in London Ont.((519 451 1116).Cost was less than $700$C.I cannot impress upon Boler owners what an improvement in tracking and trailering the new Dexter axle made.I recommend to anyone doing a rebuild to replace the axle as a matter of course.For the cost,it is a no brainer.

MAXIME

Hello Ian, I owned for 3 years now a 1980 boler 13′, likely my axle was replaced by previous owner. It seems the torsion axle arms are towards the back of the trailer, with an up angle still. Wheels seems to be well positioned, no issues. Have you heard of such setups that would have been like this on the original, or would this have to be a modification from previous owners, and if so, would it be a problem? Many thanks

Ian

Yes some of the later versions of the 13′ did have the axle installed with rear facing arms (the correct way LOL).

Joel

Hello Ian:

I recently purchased a travel trailer and was checking the wheel bearings and I unknowingly jacked up travel trailer on the outer area of the torsion bar (near the spindles) I used a wooden block as a cushion between the the jack and the axel. I don’t appear to have caused any damage on the outside of the casing but if I did damage the torsion bar what should I look for for signs of damage?

Its a 3,200 lb trailer.

A

I really appreciate your help,

Ian

Jacking on the axle can cause the axle to bend causing an alignment problem with the wheels. Usually there will be no indication on the axle anything has happened but will show up after a few trips when the tires start wearing prematurely. There is also a good chance that no damage was done in your case, keep an eye on your tire wear, make sure the tires are fully inflated and in the future only jack up your trailer by the frame

Joel

Ian: Your awesome. Thank you for your help and quick response. I will definitely keep an eye out for premature and unusual tire wear.

DJ Davis

Here’s a torsion axle question: will the axles “last longer” if you jack up the frame of the trailer and place it on jack stands to take the weight off of the torsion axles when in storage?

Ian

Yes it will. The axle will still age over time as the elastomer slowly deteriorates but jacking up and supporting the by the frame during storage will reduce extended compression on the axle elastomer, thus extending the service life of the axle.

LJ

I have a 13 foot 1979 Scamp camper. Will your axle fit this model?

Ian

Both boler and Scamp used similar rubber torsion axles so the same information would apply.

I don’t sell axles, look on the Dexter or FlexiRide website for local suppliers.

NOTE: the FlexiRide suspension arms are 1.5″ shorter than the Dexter meaning your axle will need to be relocated to keep the wheels centred in the wheel body arch.

Jason

Ian, I have a 1977 Triple E Surfside that originally came – like the Boler – with a 10 degree up torsion axle. The mount on my camper is high profile. My question is whether – assuming I have appropriate clearance – I can replace that stock axle with a low profile 0 degree (neutral) axle. The low profile neutral axle is a couple hundred dollars cheaper, and my thought is that the 10 degree up angle essentially equalizes with the 1″ profile of the bracket.

Interested to hear your thoughts

Ian

The simple answer is yes you can use a zero degree axle on your Surfside. With a boler because the axle is mounted “backwards” with the suspension arms pointing forward the arms need to angle up slightly for optimal operation. I believe your Surfside the suspension arms face rearward so a zero or even a slight positive angle is acceptable. Please correct me if I am wrong about your axle arm orientation.

Larry Cote

This site is very helpful! My 1981 Casita has the leading arms pointed forward. The frame bends upward due to the step up in the dining area. So there doesn’t appear to be an option to install a trailing arm. Will the Dexter axle #9 fit when I turn it around to face forward? It looks like it would. My axle is welded on. Somewhere I thought I saw a mounting bracket that could be installed to avoid welding and harming the new axle during installation.

Ian

Hi Larry, I am not completely familiar with the Casita frame (I am assuming you have a 13′ Casita), but as they say, anything is possible. There is no real advantage to installing the axle in the trailing arm position as long as the leading arm uses a zero to 10 degree up angle of the suspension arms. Bolting an axle to the frame, although easy, is not recommended. When you drill a hole through the frame rails it weakens the frame and creates a stress point where cracks will develop. As for brackets, yes, if you have a low profile bracket mounted on your axle then you can weld the Dexter Frame Spacer Kit to the frame, the axle can then be bolted to the spacer bracket (BTW a good welder or machine shop could easily make a similar bracket).